I’m a mechanical engineer with a passion for data analysis, control systems, automation, and design.

My main focus is designing, testing, and building prototype instrumentation and medical devices.

Education:

Georgia Institute of Technology - College of Engineering

Master of Science in Mechanical Engineering: August 2018 – May 2020

Bachelor of Science in Mechanical Engineering: August 2013 – May 2017

What I’m working on:

I’m currently doing contract work with a local physical therapist to help him update his budget-friendly dynamometer to better compete with the very expensive competition. Specifically I am updating the electronics to increase the sample rate from 80Hz to the industry standard 500Hz while maintaining a high force resolution.

Previous Projects: Good Filling

This is one of my favorite jobs I’ve worked on so far! We, as a full-time team of 4 people, got an entirely new kind of Internet of Things (IoT) vending machine designed, running, built, and optimized in a year! I was the lead on all things design and engineering.

More specifically, I:

Designed and iterated on a modular and configurable Point of Service (PoS) automated vending machine for refilling household products. System design included: all mechanical systems, electrical wiring and routing, fluid routing, all low-level (microcontroller) programming, and some C++/C# integration programs.

Worked with the Chief Technical Officer (CTO) to source all parts (electrical and mechanical) for the vending machine.

Designed, soldered, and optimized a custom Printed Circuit Board (PCB) to drive the vending machine’s electrical components.

Programmed a custom DC motor driver software optimized for our use case that is open-source and available as a library hosted by Arduino. (Linked here; Thank you to JJ O’Brien for the Dev-ops help!)

Aided the programming team in programing the backend of the kiosk (.NET 7.0-8.0 Maui based Windows machine).

Worked with multiple manufacturing companies to optimize the designs for production with ease of manufacture, cost, and consistency in mind.

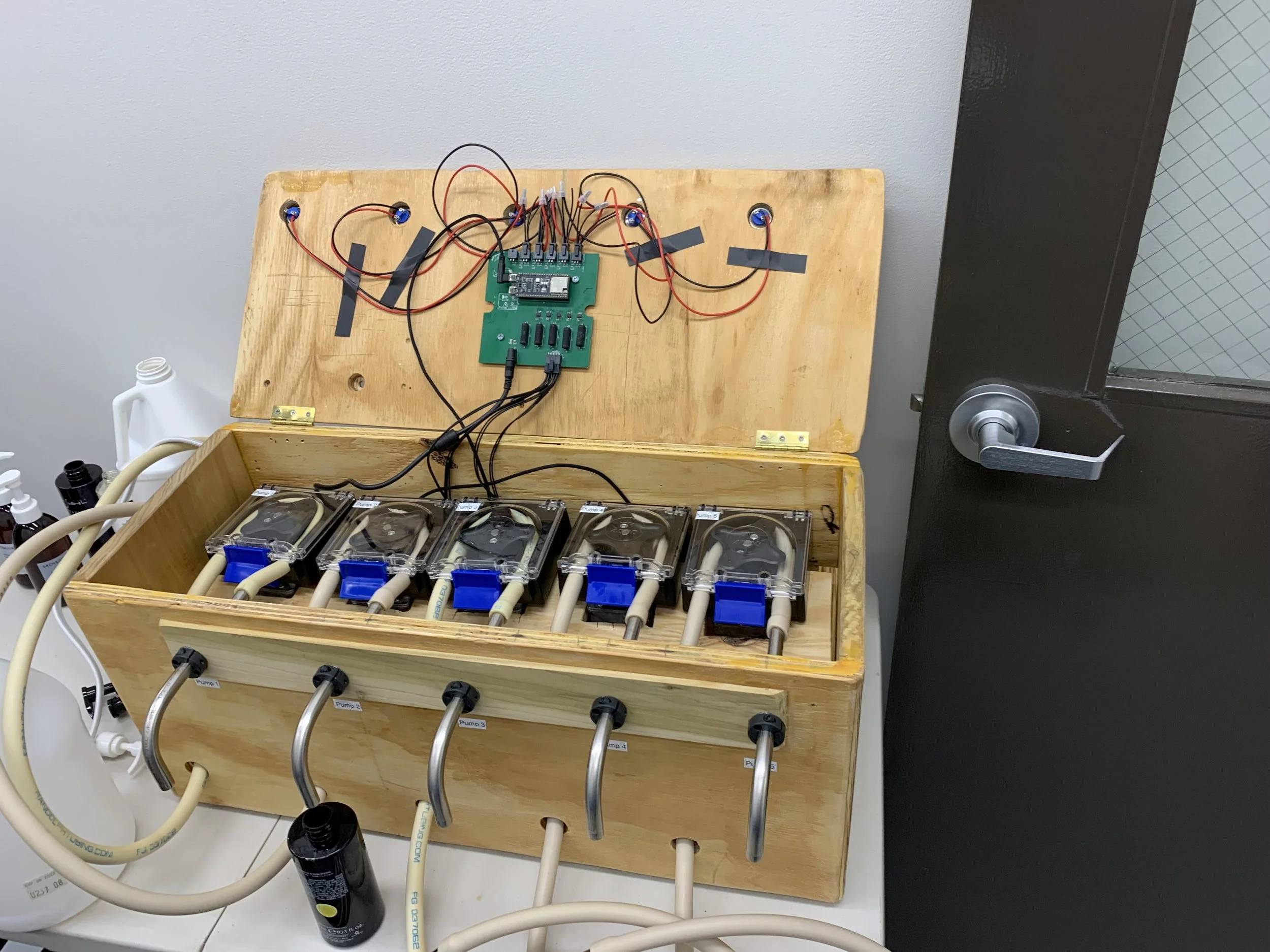

I mentored an upcoming engineer to help them gain experience and confidence in working with technical design and communication. Together, we designed a prototype soap bottle filler for use by hotels to lessen the workload with the switch to reusable bottles. This prototype included a custom PCB design, designing the machine to be both ergonomic and simple, and producing a custom wooden enclosure to house and protect the electrical components and keep things neat.

Above is an image of GoodFilling.com that shows the machine I designed: The Dispensing Station! Each of the modules has 4 separate pumps for different products and multiple modules can be connected to the same Kiosk. Care was taken to allow for ADA compliant accessibility as if it were a sink.

Above is a picture of the inside of our prototype bottle filler for the hotel industry as they transition from disposable soaps to larger, refillable containers. It was a ton of fun to adapt the things we learned while designing “The Dispensing Station” and work with an upcoming engineer!

Previous Projects: Tutoring

I’ve tutored Math, Science, and Engineering for over 10 years now! I am retired from it now officially but may volunteer to help out if someone really needs it.

More specifically I:

Tutored Math, Physics, Chemistry, and Mechanical Engineering from high school through undergraduate level.

Instructed students in mathematical and scientific concepts, helping them develop an understanding that leads to technical literacy and practice test-taking skills.

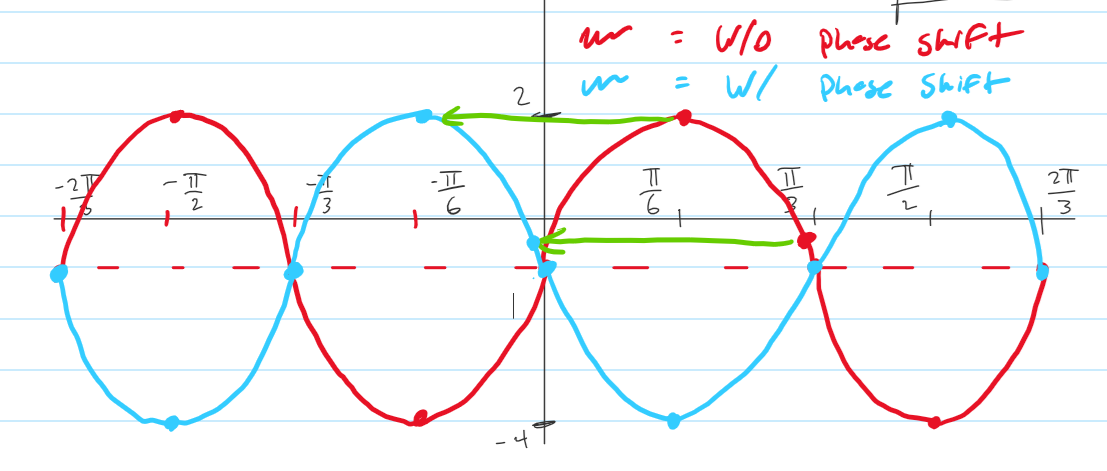

An Actual Drawing I used to explain phase shifts of sine waves to one of my pre-calc students.

Previous Projects: MRI Compatible Exercise Equipment @Emory University Radiology Department

These projects had some of the most interesting design challenges I’ve worked on. I had to design machines that fit into the small bore of an MRI machine while no ferrous material was allowed to be in it or it would become a dangerous projectile.

More specifically, I:

Designed and prototyped an MRI compatible isometric leg press device for use in validating or invalidating the efficacy of the use of certain exercises in the rehabilitation of stroke survivors. (Summer 2019)

Led and participated in a series of group exercises to further the understanding of how MRIs function and translated this knowledge into optimal use and design of medical devices. (Summer 2019)

Designed and prototyped an MRI compatible isometric knee extension/flexion exercise device for use in studying the mechanical properties of loaded and unloaded leg muscles. (Summer 2018)

This was very interesting because in the end I settled on a dual claw-like design that could be used in either flexion or extension of the knee by simply changing which direction the claws were oriented.

This is the prototype I made for the isometric leg press machine. The user would be held in place by shoulder straps and would be able to push against the footplate. A sensor inside the footplate provide data for the studies.

Previous Projects: Wheelchair In-Seat Activity Tracker & Others @ Georgia Institute of Technology’s REAR Lab

I started working at the Rehabilitation Engineering and Applied Research (REAR) Lab as a student and began honing my engineering skills by doing data analysis using MATLAB. After graduation, I began working part-time doing data analysis and helping run some of the studies that were being done. I helped with building, testing, repairing, and verifying the Wheelchair In-Seat Activity Tracker (WiSAT - yes, there was a lot of humor in their naming) and took over shipping them to subjects for studies. I also ended up being asked if I was able to make a data logger since the data loggers we had ordered were taking longer than expected. One week later I had a data logger working and able to use. Admittedly it was meant to be a temporary solution so we could keep working while the real data loggers were made, but when I visited a couple years after I had left they were still using the logger I had made.

More specifically, I:

Measured and analyzed pressure data for wheelchair seats and applied this knowledge to the design of seat cushions and wheelchairs to reduce pressure ulcer development to improve the health and comfort of people with limited mobility.

Aided in the processing and analysis of pressure data to determine the effectiveness of certain leans and positions for pressure relief for people with limited mobility.

Built a data logger to measure and record pressure data for testing new pressure mat layouts.

Facilitated multiple team research studies by maintaining communication between the research group and affiliate company, producing instrumentation to be used in the studies, and analyzing data gathered.

Publications

Sonenblum SE, Maurer CL, Hanes CD, Piriano J, Sprigle SHJAT. Everyday use of power adjustable seat height (PASH) systems. 2021;33(6):297-305.

Skills

Computer: Microsoft Office; Windows, Mac, and Linux (basic) Operating Systems.

Programming Languages: Java; MATLAB; C/C++/C#; Python; Assembly (basic).

CAD Software: SOLIDWORKS, Autodesk Inventor.

Mechanical: Milling, lathe, various hand tools

Electrical: Circuit design, PCB design.

Languages: English - native; French - basic.